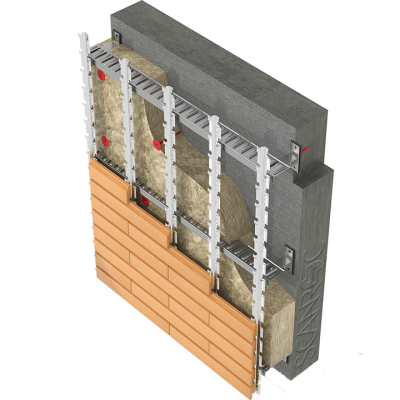

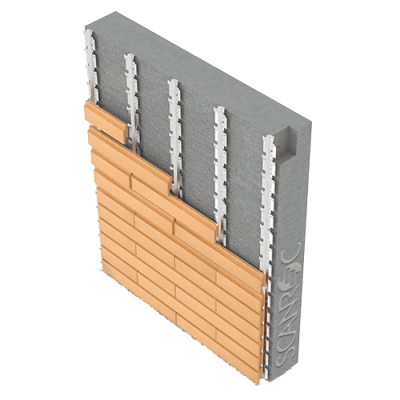

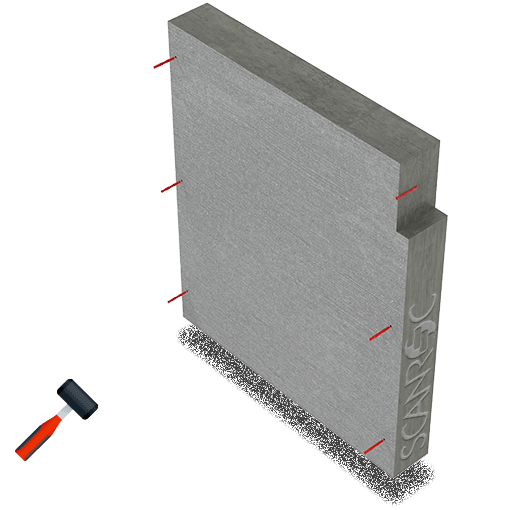

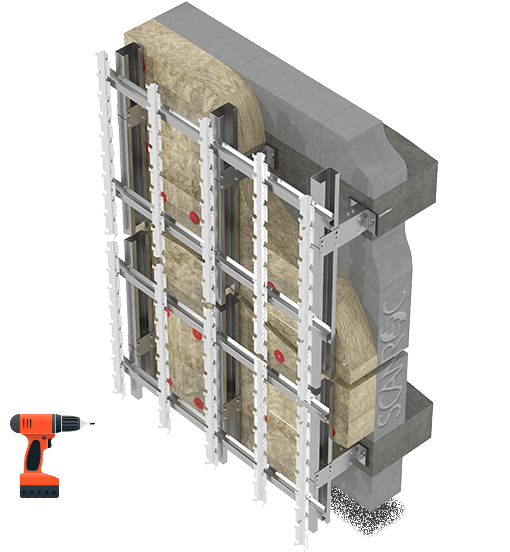

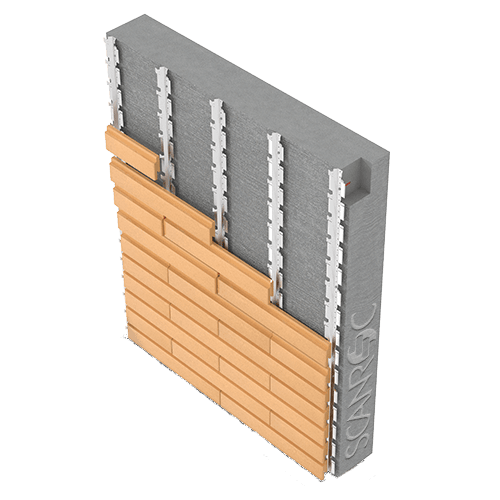

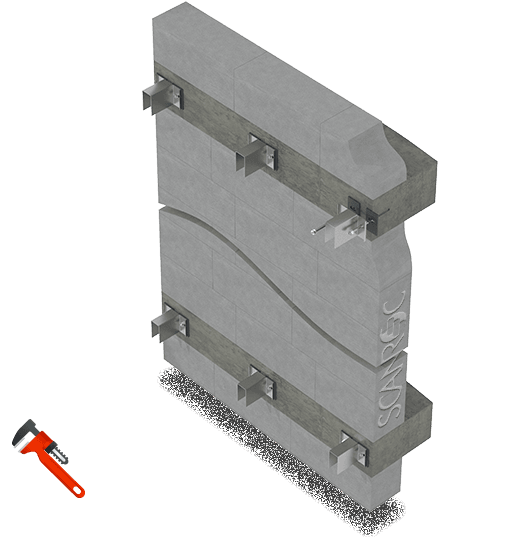

SCANROC is ventilated facade systems, which consists of a metal frame structure attached to the outside of the wall, clinker or concrete tiles attached to the frame and a heat-insulating layer or without

Ventilated facade in summer

Ventilated facade in winter

Construction benefits of SCANROC facade systems

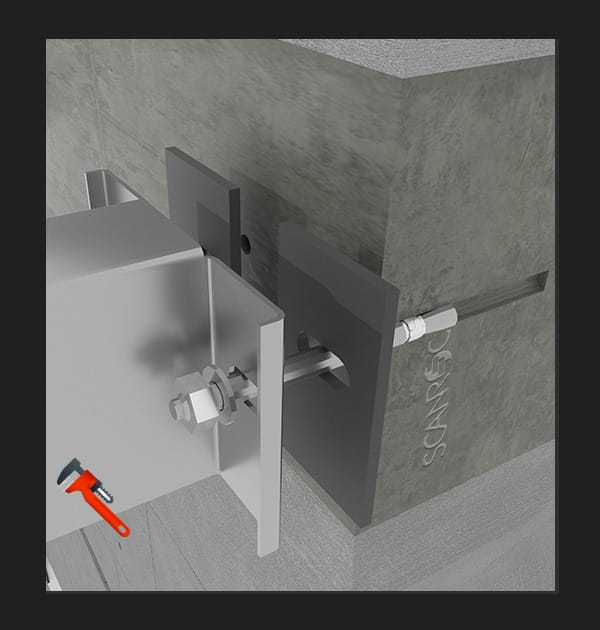

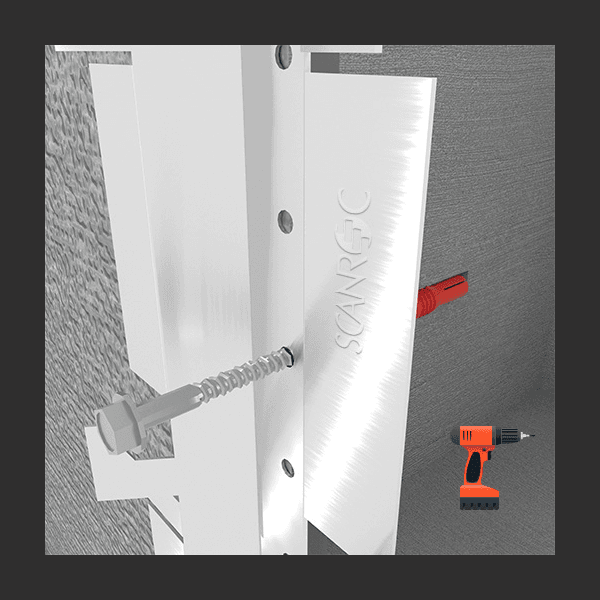

Fast and easy installation

This is the fastest and easiest method of installation that do not is required special tools, mortar, adhesive, grout, wide scaffolding. SCANROC system has the integrity look of the tradition masonry method but rapid cladding saves the construction time, and also speed time to training labor and allowing the newcomers attraction. Due to the ease of installation, which reduces the number of operations and the complete absence of "wet" processes, SCANROC systems speed up the completion of facade works almost three times compared to, for example, facade plaster with insulation. Significant resource savings, eliminated expenses of extra foundation or the labor cost associated with brick masonry, cost of logistic volume, site storage, equipment and machines operating costs are reduced.

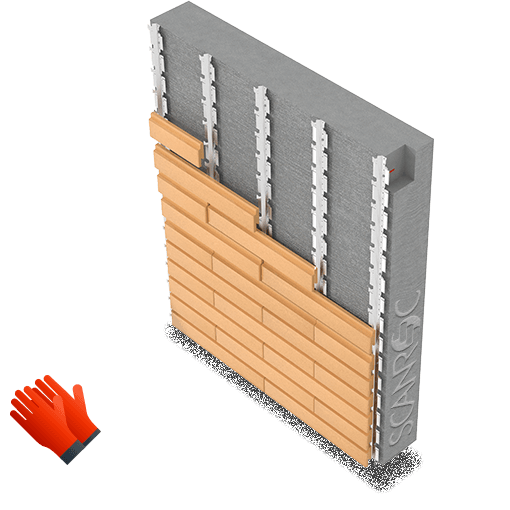

All-weather installation

Since the SCANROC system is not tied to "wet" processes, installation work can be performed in any season. The dry process allows for a continuous construction regardless of any weather conditions, sub-zero temperatures, etc.

Grout is unnecessary

This thesis is relevant when compared with systems that include large-format shields with tiles glued to them. In these comparisons, missing processes related to grouting is not the only advantage of the SCANROC system. There are much more powerful ones, such as preventing the collapse of the tiles, the absence of deformation of the tiles, etc.

Repairability

All elements of the SCANROC facade are easily repaired. for example, it takes several minutes to replace a damaged tile. For this, you need to leave a small repair kit after construction. In addition, the installation of air conditioners and other hanging equipment is a simple process — a fragment of the facade can be easily disassembled, done and put back together without personal effort, unlike, for example, ceramic granite.

Excellent facade aesthetics

Wide brick-style assortment of facade tiles in color, texture and size gives the flexibility in design for huge needs in renovating historical buildings and new local-style construction, from classics to modern.

Resistance of facade tiles to ultraviolet

The color of the facade tile does not fade. Tiles of any collection are resistant to ultraviolet radiation due to the addition of light-stabilizing components to the composition of concrete tiles, and ceramic tiles have such natural properties. All components of SCANROC systems are environmentally friendly.

Resistance to extreme weather conditions

High strength of facade tiles (SCANROC bending strength limit is 60 kg/cm2), its firm fixation and reliability of the system is confirmed by the conclusions of examinations. High seismic resistance. The seismic resistance of the SCANROC system is confirmed by the findings.

Maximum fire resistance

Class of fire resistance of the NG system. No combustible materials are used in the system. Important: relative to aluminum sub-systems, which lose their bearing capacity at t≥260°C, SANROC steel systems can withstand 600°C, but we understand that there are no combustible materials in the SCANROC system.

Installation on high-rise buildings

Height restrictions up to 100 m. Unlike other facades, which use combustible materials, incl. polymer, with flammability class Г1-Г2, no combustible materials are used in SCANROC facades, and in terms of its physical and mechanical properties, SCANROC is unique in its kind.

Rationality

Significant resource savings, eliminated expenses of extra foundation or the labor cost associated with brick masonry, cost of logistic volume, site storage, equipment and machines operating costs are reduced.

Complete exclusion of moisture from entering the system

Ceramic and concrete facade tiles and the structure completely prevent moisture from entering the system. All horizontal seams are reliably closed by the upper row of facade tiles. In addition, the existing ventilation channel between the facade tile and the thermal insulation creates an air draft, which picks up the water vapor coming out of the thermal insulation and effectively takes it out of the system.

High frost resistance

Frost resistance exceeds F>150 cycles, while the tile is guaranteed to be held on the antennae of the racks, which is confirmed by relevant examinations. Metal capacity of the frame of the subsystem. Metal parts are made of calm tool steels of high quality production and have a thick layer of hot-dip galvanizing. The design of the subsystem allows you to face any architectural forms with minimal consumption of materials.

Construction benefits of SCANROC facade systems

SCANROC system has the integrity look of the tradition masonry method but rapid cladding saves the construction time, and also speed time to training labor and allowing the newcomers attraction.

Due to the ease of installation, which reduces the number of operations and the complete absence of "wet" processes, SCANROC systems speed up the completion of facade works almost three times compared to, for example, facade plaster with insulation.

Significant resource savings, eliminated expenses of extra foundation or the labor cost associated with brick masonry, cost of logistic volume, site storage, equipment and machines operating costs are reduced.

All components of SCANROC systems are environmentally friendly.

High seismic resistance.

The seismic resistance of the SCANROC system is confirmed by the findings.

All horizontal seams are reliably closed by the upper row of facade tiles.

In addition, the existing ventilation channel between the facade tile and the thermal insulation creates an air draft, which picks up the water vapor coming out of the thermal insulation and effectively takes it out of the system.

Metal capacity of the frame of the subsystem.

Metal parts are made of calm tool steels of high quality production and have a thick layer of hot-dip galvanizing. The design of the subsystem allows you to face any architectural forms with minimal consumption of materials.

Technical information

- SCANROC DETAIL EN new, 8.20 MB

- TECHNICAL INFORMATION, 2.02 MB

- Test report of hydrothermal behaviour

- Test report of resistance of tohorizontal point loads

- Test report of resistance to hard and soft body impact

- Test report of thermal resistance

- Test report of water vapour permeability

- Test report on mechanical tests of a cladding kit

- Test report on resistance-test of subframe brackets of vertical and horiz load