Purpose of the SCANROC KEFSVOK -10 installation system

Installation of the ventilated SCANROC KEFSVOK -10 ventilated facade is carried out on walls made of low density cellular concrete (D <600).

Fastening of the SCANROC KEFSVOK -10 system is carried out directly in interfloor floors.

The SCANROC KEFSVOK -10 system is a patented system

The SCANROC KEFSVOK-10 system, like all other SCANROC systems, is highly reliable and durable.

All SCANROC ventilated facade systems have been certified in Ukraine, Western Europe and other countries.

SCANROC ventilated facades are exported to Belarus, Kazakhstan, Scandinavia, Baltic countries, Czech Republic, Slovakia, Germany, Denmark, Holland and even Australia.

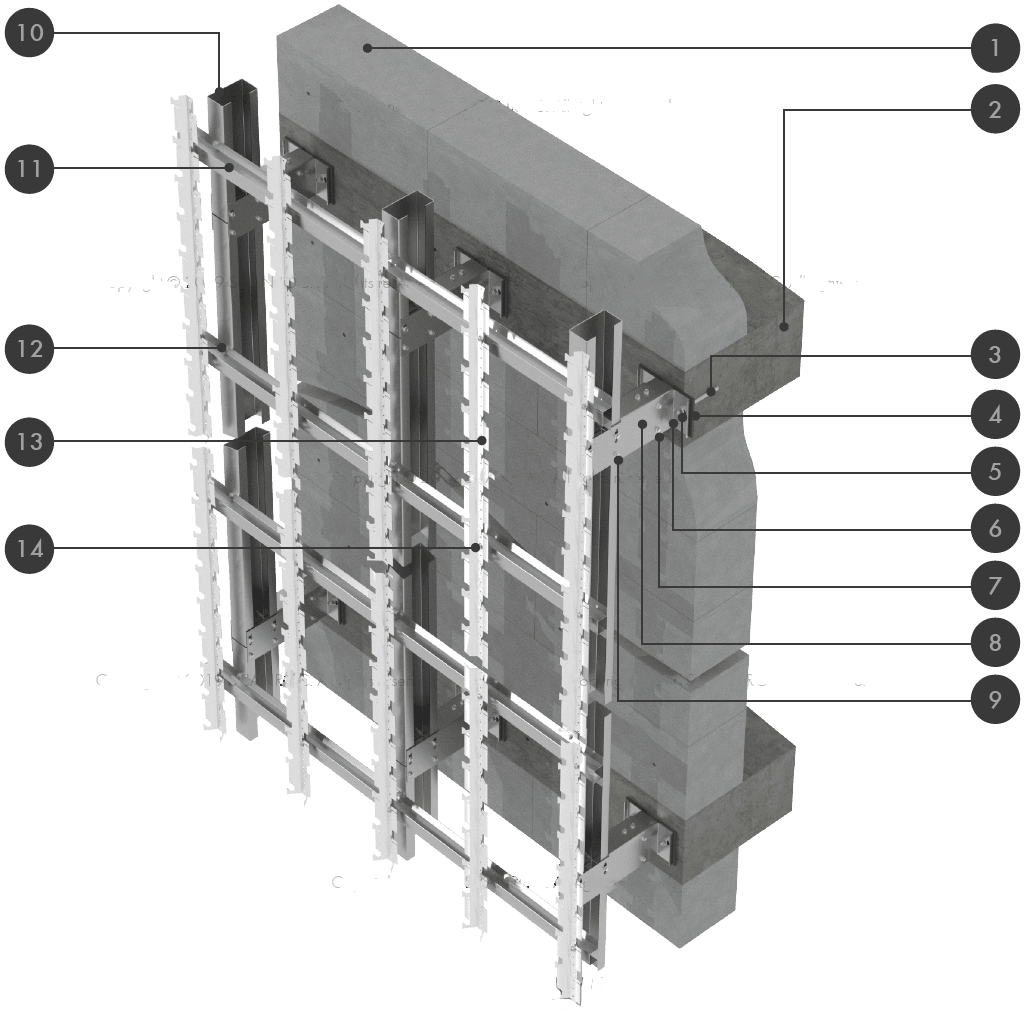

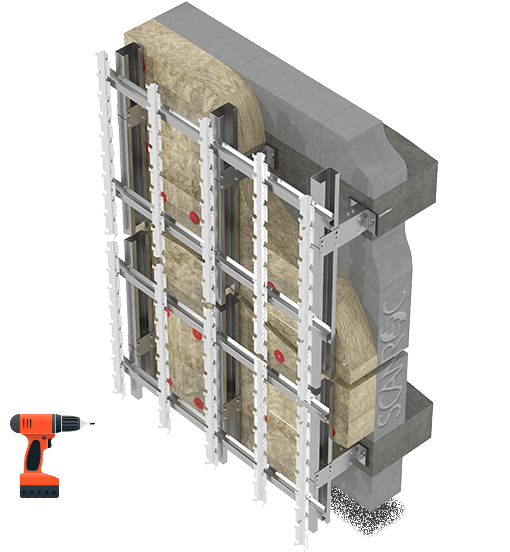

General view of the SCANROC KEFSVOK -10 system

All SCANROC KEFSVOK systems consist of three groups:

- structural metal part

- heater

- front [SCANROC facade tile]

Explanation of the scheme:

- Blocks of cellular concrete, such as gas blocks

- Reinforced concrete floors

- Mounting points [the whole system is fixed exclusively in reinforced concrete flooring]

- Heater

- Structural metal part

- Facade tile SCANROC

Note: the red plane in the figure indicates a conditional section of the wall.

The structure of the structural metal part of the SCANROC KEFSVOK-10 system

All metal parts of the system are made of high quality European hot-dip galvanized steel.

All screws and anchor bolts are hot-dip galvanized.

Explanation of the scheme:

- Blocks of cellular concrete

- Reinforced concrete floors

- Anchor bolt 10×100

- Termoizolyatsіyna laying SCANROC T-3

- Nut

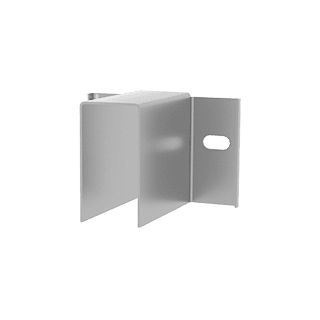

- Console SCANROC K-180

- Hot dip galvanized screws 6,3х19

- SCANROC P-1 slider

- Hot dip galvanized screws 6,3×19

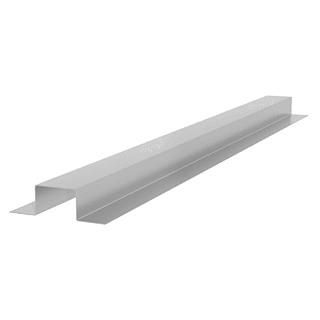

- Rack SCANROC C-100

- Crossbar SCANROC R-6

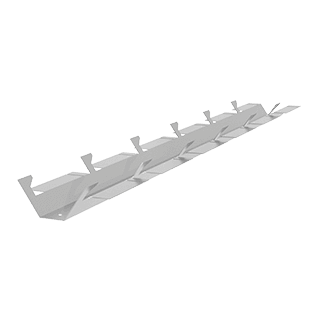

- Rack SCANROC C-1

- Hot dip galvanized screws 4,8×13

The SCANROC C-1 is directly attached to the SCANROC tile.

The diagram shows the placement of SCANROC C-1 racks in 600 mm increments for LONG Format [600 × 100 mm] and LARGE Format [600×200 mm] tiles. To hang the tile cottage format COTTAGE Format [300×100 mm] the number of racks SCANROC C-1 is doubled in increments of 300 mm.

Accessories SCANROC KEFSVOK -10 systems

Installation stages of the SCANROC KEFSVOK-10 system

Perform markup according to the project. Drill holes to install anchor bolts.

Perform markup according to the project. Drill holes to install anchor bolts. With the help of 10×100 anchor bolts, screw the consoles to the reinforced concrete interfloor floors, pre-installing the T-3 insulation linings one pair under each console.

With the help of 10×100 anchor bolts, screw the consoles to the reinforced concrete interfloor floors, pre-installing the T-3 insulation linings one pair under each console. Mounting point of the SCANROC K-180 console to the reinforced concrete interfloor floor. The brackets are secured with two anchor bolts for each mounting point.

Mounting point of the SCANROC K-180 console to the reinforced concrete interfloor floor. The brackets are secured with two anchor bolts for each mounting point.After mounting the consoles, be sure to check the tightening of the nuts.

The SCANROC P-1 slider connects the SCANROC C-100 rack and the SCANROC K-180 console. With the help of the slider, the flight length of the C-100 rack is regulated. Mounting of the slider P-1 to the console K-180 is performed with the help of hot-dip galvanized screws 6,3×19 (6 pcs for each attachment point).

The SCANROC P-1 slider connects the SCANROC C-100 rack and the SCANROC K-180 console. With the help of the slider, the flight length of the C-100 rack is regulated. Mounting of the slider P-1 to the console K-180 is performed with the help of hot-dip galvanized screws 6,3×19 (6 pcs for each attachment point). Before installing the insulation mats, it is necessary to cut through the holes through the knife for the projecting elements of the consoles. After the mats are hung, the holes in the wall (everywhere the mats) are drilled, and umbrella dowels are used to hold the mats. Technology of fastening of thermal insulation is carried out in accordance with building codes.

Before installing the insulation mats, it is necessary to cut through the holes through the knife for the projecting elements of the consoles. After the mats are hung, the holes in the wall (everywhere the mats) are drilled, and umbrella dowels are used to hold the mats. Technology of fastening of thermal insulation is carried out in accordance with building codes. The SCANROC C-100 rack transfers the load from the SCANROC decorative-protective part to the wall and attaches directly to the SCANROC P-1 slider with the help of 6.3×19 hot-dip galvanized screws (8 pieces for each attachment point).

The SCANROC C-100 rack transfers the load from the SCANROC decorative-protective part to the wall and attaches directly to the SCANROC P-1 slider with the help of 6.3×19 hot-dip galvanized screws (8 pieces for each attachment point).Importantly! The heater should not touch the SCANROC C-100 rack. Maintain the required clearance according to the project.

General view of the power unit for fastening the SCANROC system to the concrete floor.

General view of the power unit for fastening the SCANROC system to the concrete floor.Vertical stand SCANROC C-100 is cut in factory length according to the project (inter-storey distance). This greatly speeds up the installation process and provides the required quality of the structural system.

Connection of the SCANROC C-100 racks is vertically jointed at the joints of the P-1 slider.

The function of the SCANROC P-6 crossbars is to build a foundation for the placement of the vertical SCANROC C-1 racks, onto which the SCANROC facade tiles are directly hung.

The function of the SCANROC P-6 crossbars is to build a foundation for the placement of the vertical SCANROC C-1 racks, onto which the SCANROC facade tiles are directly hung.Crossbars SCANROC R-6 join the racks SCANROC C-100 with the help of hot-dip galvanized screws 6,3×19 (2 pieces for each mounting point).

SCANROC C-1 racks function as holders of SCANROC facade tiles. The SCANROC C-1 rack is fastened directly to the SKANROC R-6 crossbar with the help of 4.8×13 hot-dip galvanized screws (1 pc for each mounting point).

SCANROC C-1 racks function as holders of SCANROC facade tiles. The SCANROC C-1 rack is fastened directly to the SKANROC R-6 crossbar with the help of 4.8×13 hot-dip galvanized screws (1 pc for each mounting point).Depending on the length of the facade tiles, SCANROC C-1 racks are placed in 600 mm increments (for LONG 600 × 100 and LARGE 600 × 200 tile formats) or 300 mm (for COTTAGE 300×100 tile format). SCANROC C-1.75 joints are placed depending on other formats of SCANROC clinker tiles.

After mounting the entire system on the protruding antennae of the SCANROC C-1 racks, the SCANROC tiles are hung.

After mounting the entire system on the protruding antennae of the SCANROC C-1 racks, the SCANROC tiles are hung.The attachment is done by pressing on the tile and planting its groove on the antennae of the stand C-1.

Each tile should have 3 points of resistance – left, right edge and middle. At a minimum, every fifth row must be secured with additional anti-vandal antennae having SCANROC C-1 counters unless otherwise provided by the project.